POLYURETHANE FOAM

Whether you use it to insulate a new building, renovate or improve your existing insulation, polyurethane foam allows you to incredibly increase the energy efficiency of your building.

Polyurethane foam is obtained by mixing two components, polymers, and isocyanates, at a temperature of 40 - 45°C under a pressure of 120 bar, in this reaction the foam expands (grows) up to 100 times. It is applied by spraying on the substrate with a special Reactor that allows the specified pressures and temperatures. Precisely because of this special way of application, it can provide performances that no other material can:

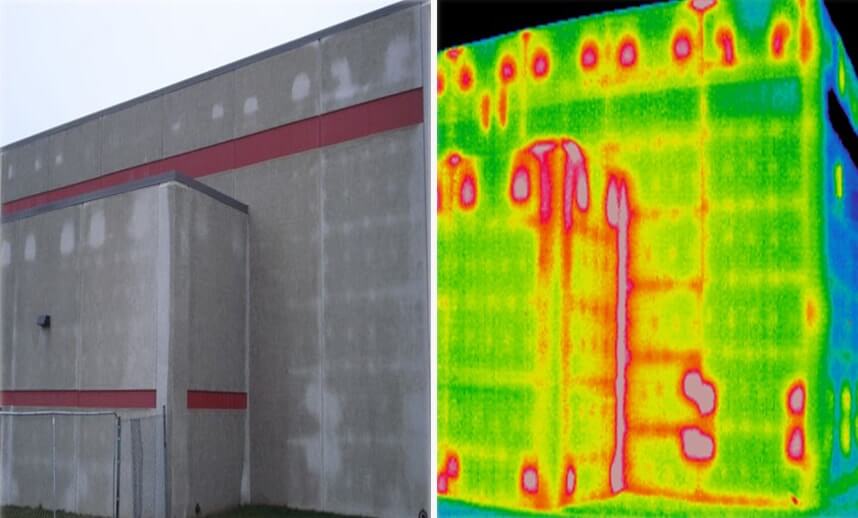

- The application of foam is completely monolithic, which means the lack of joints and seams or thermal bridges. It can be applied even in the most inaccessible places where no other technique has given a satisfactory answer (see Figure 1.1).

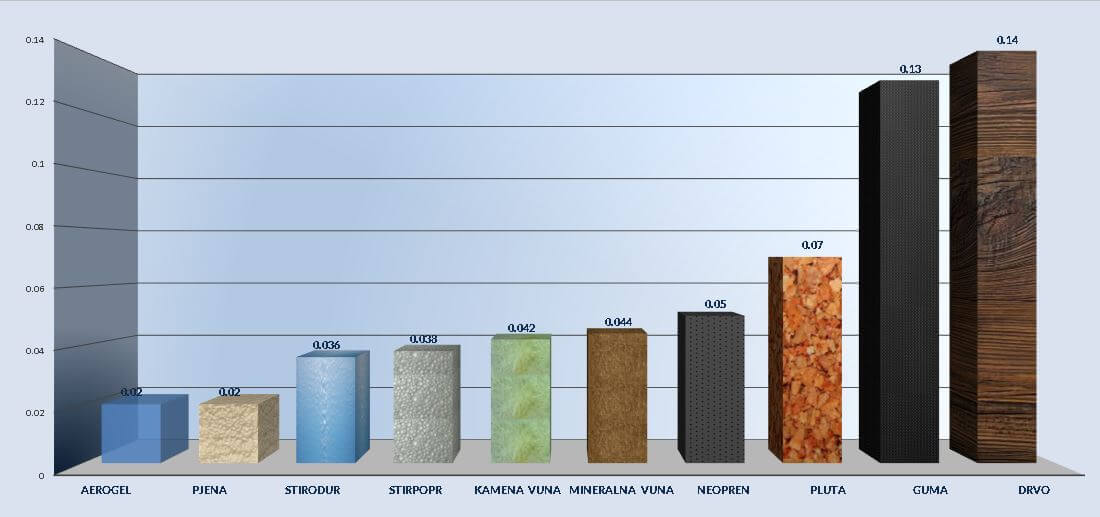

- Extremely low Lambda coefficient (thermal permeability coefficient) 0.02–0.022, significantly reduces the heating costs of your building (see Graph 1.2).

- High compressive strength up to 300kPa, can be used in coupling and reinforcement, wooden and steel structures while extending the life of the building.

- Foam has excellent adhesion to various materials such as wood, steel, concrete, etc. It can be applied both in new construction and in the rehabilitation of buildings.

- Quick and easy application of insulating spray, other layers can be applied after only a few minutes. The complete work is completed very quickly, family houses in just one day.

- Waterproof, closed cell foam has minimal water absorption.

- Sound insulation, open cell foam is an excellent sound insulator.

Graph 1.1

Coefficient of thermal permeability λ (lamda) W/(m.K) (the smaller the coefficient the better)

Graph 1.2

One of the main advantages of polyurethane foam insulation over others, in addition to fast and efficient application, and outstanding technical characteristics (better than all other insulations used in our country) are that they adhere easily too hard to reach places, creating a completely homogeneous and closed system, without joints and thermal bridges.

Places of application:

- In combination with polyurea makes the best system for flat roofs.

- Intelligent solution for removing condensation on various steel halls, a layer of 0.5-1.0 cm is enough to eliminate all your condensation problems.

- An excellent solution for all shapes of roofs, sloping and flat, due to its method of application can be applied in all inaccessible places.

- Ideal for attic insulation

- Insulation of cisterns, truck interiors, industrial ceilings, ventilation ducts and all types of pipelines, to reduce heat losses during transport and thus reduce costs.

The main division of Pu foam is into:

- Polyurethane foam - closed cells

- Polyurethane foam - open cells

Polyurethane foam - closed cells

Are much denser and more often used than open cells. It has a higher R-factor value that goes up to 3.62 for just 1cm of foam. Closed cells have higher insulating properties due to their resistance and high-water resistance.

It is thick enough to insulate the air and prevent vibrations (especially with gypsum systems) and at the same time the best thermal insulator.

To maintain its resistance, the foam of closed cells is very thick, so it resembles solid materials when it is completely formed. Its strength is not only reflected in the thermal insulation of buildings and structures, but it significantly strengthens the walls of the structure on which it is applied, and in some cases up to 400%.

It prevents the growth of molds and fungi and is resistant to all types of rodents and insects.

Ideal material for thermal insulation of new and old buildings. Easy application, low coefficient of thermal conductivity and excellent mechanical properties guarantee that this is the material of the future.

It is used for condensate removal in all prefabricated and monolithic construction systems.

High waterproofing properties!

Polyurethane foam - open cell

is most used in indoor systems. It has lower waterproofing properties than closed-cell polyurethane foam, but it is much better when it comes to vapor permeability. It also has R = 1.5 for only 1cm which is again better than any insulation materials on our market.

Thanks to its structure, open cell foam ensures high vapor permeability and is an excellent sound insulator.

Intended for insulation of roofs, attics, attics, floor slabs, as well as interior walls, masonry steel structures, partition systems, and industrial buildings, public buildings, and ancillary premises.

During and after the application, you can ask us for documents that contain information on who applied the insulation, on which surface the system was applied, which system was used during the insulation and when the work began and ended. Each application surface can be physically identified through photographs.

This data allows you painless further work in the future and the opportunity to choose the right materials for renovation in this new job.

If you need assistance or would like to learn more about this system and our services, do not hesitate to contact us by email or phone.